Products / CF SERIES

Product Images

Similar Products

| Product | Price | Unit | |

|---|---|---|---|

| CF SERIES | 0 Rials | Number |

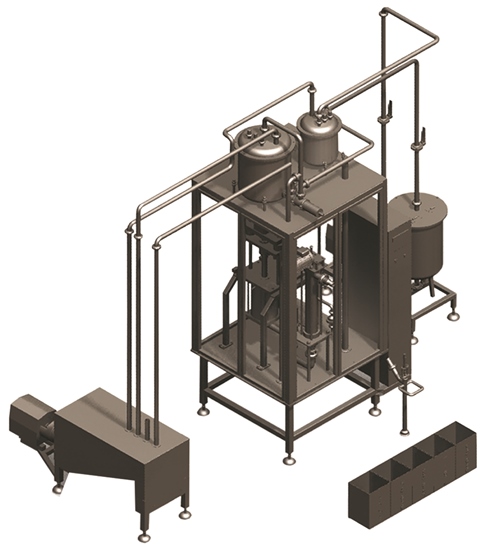

Shargh Sanat has delivered more than 40 UF Feta cheese packing line in Iran This machines designed for 0/5 -4 kilos and filled with 1-4 separate layers of cheese.the capacity of the plant is 500 cycles /h . after coagulation of the top layer of the cheese a cutting takes place through all layers cutting the cheese in to the desired number of blocks. after the cutting of cheese &expire enough time for get suitable PH ,add pasteurized salt water to canisters. after salting the canisters are sealed. The machines are designed on the basis of 20 min time for each layer coagulation. the filling nozzle is connected to the dosing system is system (servo motor drive & ballScrew) for retentate and rennet and is provided with a static mixer. befor first filling the canisters ae sprayed internally with”slip-spray”and following each filling ,nozzlesare mounted for possible spray with” anti foam”

the chasis of the machine as well as all parts in contact with the products are made of stainless steel & operation of the machine is controlled via a PLC andtouch screen control panel with a display showing all relevant data .Shargh Sanat also produces semi-automic UFcanister filling units . the unit is built on a stainless steel fram and is equipped with the following

A Stainless steel tank with level controls is mounted for the retentate.

Level controllers in the buffer tank activate the pump.

rennet / culture is from the stainless steel buffer tank measured in to the retentate line by an electrically driven cylinder dosin pump.

retentate and rennet / culture are mixed in a dynamic mixer. sanitary hose is connected to the filling gun. the filling gunis hand held and a filling is activted by a push button on the filling gun.

the unit is supplied with a special spraying gun used for spraying canisters internaly befor filling with retentate .

a cutting device is also delivered for vertical.

cutting of the cheesel layers in thecanisters. the unit is built for CIP cleaning for connecting to a central CIP plant.

Menu

Sharghsanat Industries

Other

News Letter

We do not send spam.